When it comes to transporting cargo over long distances, reliable ratchet straps are essential. However, not all ratchet straps are the same. They are designed for specific purposes and have different load capacities. So, how do you know which one is right for you? That’s where break strength and working load limit come in.

Break strength and working load limit are measurement metrics used in the rigging industry, including ratchet straps. Each component of rigging equipment has its own values for these metrics, which can often be confusing. Let’s break it down to clear things up.

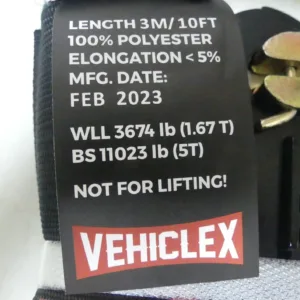

Working Load Limit (WLL): The working load limit is the maximum weight that a ratchet strap can safely handle under normal conditions. For instance, a ratchet strap with a working load limit of 8,000 pounds should only be used to secure loads up to that weight.

The working load limit is one-third of the breaking strength. So, a ratchet strap with an 8,000-pound working load limit will have a breaking strength of 18,000 pounds.

Breaking Strength: Breaking strength refers to the point at which any part of the ratchet strap will fail or break. It is determined by the weakest component of the strap, such as end fittings, webbing, or the ratchet itself. Let’s say a ratchet strap has three parts with a cumulative breaking strength of 10,000 pounds. However, if any individual component has a lower breaking strength, the overall breaking strength of the strap will be reduced to that weakest point.

To ensure your safety and the proper use of ratchet straps, always check that the straps you are purchasing are properly tagged with Working Load Limit (WLL) information. This tag will provide you with essential details about the maximum weight the strap can handle.

Stay safe and secure your cargo effectively with the right understanding of break strength and working load limit for your ratchet straps.